Insights on flow

Assessing a Plant

How much can you learn from a walk through?

Have you ever had the opportunity to visit a manufacturing plant and wondered whether you got the most out of it? Having toured a huge number of facilities with a wide range of people, we’ve seen a vast difference in what people learn and take away from those visits.

Having a structured approach can enable you to absorb more than you might expect. If you get it right, you’ll come away with a good understanding of how the plant runs, where it could improve and what you can learn and take back to your own plant.

Priorities

I once toured a large operation where we were told from the outset that safety was the number one priority. As the General Manager gave this speech, I could see a large, heavy pallet of goods precariously dangling from the racking, over a heavily congested area below. When asked what would be done about it, the GM was very dismissive. Words, actions, and attitudes were not aligned.

Businesses having clear priorities, which are commonly known, communicated and tracked, typically make quicker progress and towards their goals. Ask your tour guide, what the priorities are. Do you see that reflected in the information and measures around the plant? Do behaviours and actions align with what has been described?

Do the priorities centre around things which will bring business benefit: Customer service, Cost, Capacity, Capital or Culture?

Flow

Observe how material and information flows through the facility. Is there a logical flow from incoming goods to despatch? Where does flow slow, stop or deviate? Most tours will follow the flow from start to finish. Imagine yourself as a product passing through the process.

- How far will you travel?

- How long will it take you?

- Will you get lost or confused on the way?

- How will you know when it’s your turn at each process?

- How does information flow through the process?

If the answers don’t come easily, you’re probably looking at a turbulent flow. Turbulent flows are unpredictable and can be chaotic.

Ask what the rate of customer demand is and check if processes are running at the correct rate to meet that demand

Inventory

The amount of inventory held in work in progress on the shop floor is a good indicator of how lean the plant is. You can ask or observe the output of a process to see its rate of production. For example, if a machine produces 100 units per hour and there are 1,000 units ahead of it, there are 10 hours of inventory on the floor. The average waiting time to be processed is 10 hours, but this may vary widely if the product has to wait for changeovers or batches. It may be worse still if orders are cherry-picked by the operator.

Take a look at raw material and finished goods. Can you estimate how many hours/days/weeks of inventory there are? Observe, reflect and think about what might be possible.

Visual management

What is being displayed on the shop floor? In the best plants, you’ll know within two seconds if they are having a good or bad day.

Check if the data is up to date and whether it reflect the priorities mentioned earlier. Look for evidence about what is happening to address the priority problems. You can find out a great deal by speaking with the operators asking operators how they know if they are having a good day. Often they will explain what’s going well, or not so well and why. Check to see if that matches the visual management systems.

Imagine yourself as a supervisor on the shop floor. Could you pass the area at a normal walking speed and know whether you need to stop and help?

Complexity

Many plant managers will explain how their process is special and more complicated than any other you may have seen. The reality is that many plants have complexity and that simplifying it is more effective than trying to manage complexity.

Review the different items passing through the plant and think about what the product tree looks like. In a car assembly plant, the process involves many parts coming together to make one, large final assembly. In a paper plant, there may be one raw material which ends up in a huge number of finished variants. Look at where the complexity is and think about how you would simplify it if it was your plant.

Equipment

Capital intensive operations will have a different focus than labour intensive ones. When looking at the machinery, don’t be taken in by the age or sophistication of the equipment. We have seen excellent plants operating with 50+ year old equipment. A new piece of equipment that is unloved may well be outperformed by an old piece of equipment which is run and maintained effectively.

When speaking with an operator of an old rolling mill, she showed me her manual monitoring of overall equipment effectiveness. The sheets were handwritten. The operator owned the process, knew it’s performance and took immediate steps to rectify any problems.

In contrast, I visited a company with the latest CNC machines with sophisticated monitoring systems. The data was held in a remote server, belonging to the engineering department which nobody ever looked at. The operator had no idea what the effectiveness of the machine was, and nobody felt responsible for improving it.

I’ll leave you to guess which process was more effective.

Culture

One of the most subjective things you can assess is culture – it’s also one of the most important. Look at the interactions between the teams. Look to see if there is open communication, regular feedback and a genuine interest in performance. Companies with a great culture exude passion.

Is everybody respected for the role they play in the company and given a chance to succeed? When you come away, do you feel that everybody cares about the success of the business and the capability and success of the people involved in it?

Next steps

It takes a great deal of experience and knowledge, combined with a structured approach to read a plant. The above tips will help you start on the journey. If you need to really understand your own plant, benchmark against other operations, or know more about a plant you are considering acquiring, we are here to help.

+44 151 374 2802

You’ll be amazed by what we can tell you from a walk through.

Plant assessments

Operational due diligence

Operational insight

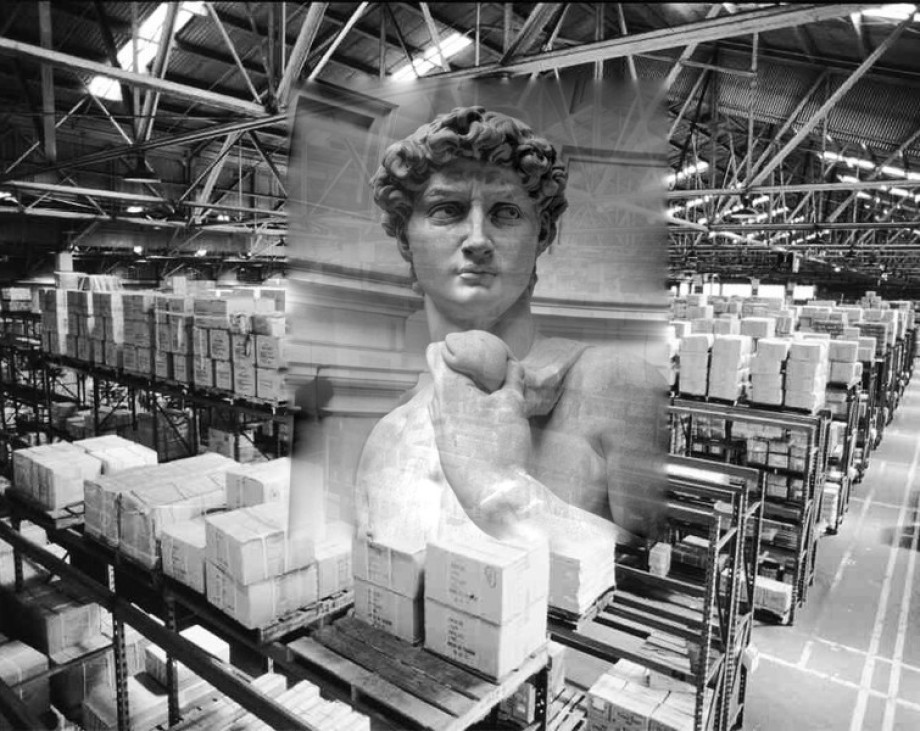

Is David Hiding in Your Factory?

Revealing the hidden masterpiece

When Michelangelo started carving his masterpiece David, he didn’t look at the huge block of marble and consider materials he could add to it. He knew David was in there and he just had to chip away the parts which weren’t David.

Often, it’s the same in your factory. Too often companies will look at what can be added when everything that’s needed to make the products is already there. So before thinking about introducing automation, sophisticated planning systems, and bigger premises, take a look at what doesn’t belong in your perfect factory and start chipping away at it. Work to free your factory from everything which isn’t needed, just as Michelangelo freed David.

You may find excess inventory stacked around David – often, by working to remove it, you’ll start to see the basic form take shape.

What about those snaking lines that look like they were designed by a conveyor salesperson? Do they form part of your pièce de résistance? – probably not, let’s see if we can shorten them. Now, what about that extra space, which attracts unnecessary items; whittle it down to what’s required. That should help take down all that excessive walking and transport of materials.

As you practice on the rough cuts, you’ll become more skilled in your craft. Look closely at the planning systems - are they trying to manage complexity, or simplify it? Chisel out any unnecessary bureaucracy. By now, things will be flowing more easily and lead time should be reduced if you’re doing things right.

David’s becoming recognisable, but there is plenty of detailed sculpting left to do. As the large pieces of waste material come off, the chisel strokes become more precise. Defects become more apparent. There’s nothing to be gained by being too brutal at this point, we don’t want to remove parts of David.

Not everybody can be a master sculptor, so a little filler may be required to fix the parts which didn’t go quite to plan. The filler will need to be applied well, if it is to stick.

It’s painstaking. Every detail needs to be considered. You still have to step back from the workpiece regularly and take a look, recall the vision and make sure you’re carefully honing in on David.

Creating a factory masterpiece takes passion, vision, and attention to detail. There will always be parts which need smoothing, polishing and careful maintenance, but with great efforts come great rewards.

Happy sculpting.

www.virrata.co.uk factory sculptors

Six Types of Flow

Does your company have a progressive tendency?

Flow:Verb

- To proceed continuously and smoothly

- Glide along as a stream

Flowing – Progressive tendency

Many of us are familiar will the concept of creating flow through organisations, but how carefully have you considered how material and information flow through your business? Do you have a progressive tendency in everything you do? Here are some flows which may sound familiar.

Rapids

The pace is fast – things flow quickly, however the path is uncertain and littered with danger. It takes energy and provides exhilaration for those brave enough to take the journey, but no two journeys are ever the same. Outcomes are unpredictable and there may be casualties along the way. Bringing your adrenaline junkies on to a safer flow takes skill and persuasion.

Mill pond

Flow is static, the stagnation can encourage bacteria and parasites to thrive in this environment, ultimately becoming a major hazard. Major changes may be required to restore flow to create a healthy environment. Getting the mill wheels turning creates flow and helps bring new oxygen and life.

Canal locks

Strict rules apply at each stage of the flow. The destination is clear, as are the steps to get there. Following the rules helps provide a predictable outcome, however this comes at a heavy cost in terms of speed. Rules are based on longstanding techniques and are difficult to change. Great expertise can still bring innovation.

Reservoir

Large stocks provide a controlled flow to downstream users. The inventory provides protection from periods of low supply, but comes at a great cost to maintain. In periods of excess supply, valuable resources cannot be harnessed and our allowed to flow away. At times of drought, customers may have to reduce consumption. Getting the right balance of inventory, time and capacity ensures availability at least cost.

Ocean

Flows cover great distances creating a virtual conveyor belt. The major flows are generally predictable, but local variables make for chaotic, unpredictable variation at a micro level. Sub flows beneath the surface are not easily observed or understood. Understanding and harnessing the flows allows oceans to be crossed

The Dubai Fountain

Demand can be met at the flick of a switch. The results are impressive to observe – so much so that they draw people in - customers. Flow is precise, repeatable and configurable. Investment is high, as are returns. The investment in automation makes this a barrier to most new entrants. Knowing when to invest in automation takes skill and judgement.

So what does this mean for my business?

The above examples are far from exhaustive and every business will have its own version of flow, just as every river has its own path, speed and individual factors which affect its flow. When you think about your business, consider where flow deviates, slows, stops or is not equivalent to demand. By understanding this you’re on your way to improving your progressive tendency.

Want to know more or see how your flow problems can be solved? Get in touch www.virrata.co.uk, info@virrata.co.uk

- it’s all about flow

I told you - I'm working on a chair

Is there a standard recipe for improvement?

A colleague of mine shared a story recently. It made me reflect on improvement programmes across different businesses. It went something like this.

Two students studied engineering design together at university. Hans joined a Danish furniture manufacturer and Lucas joined an architect's practice.

Some years later they bumped in to each other at an airport. "What are you working on?" Lucas asked Hans. "I'm working on a chair – how about you Lucas?". " I'm working

on an apartment block". They chatted for a while before catching their flights.

A year later they met up again, passing through the airport. Hans asked "what are you working on now then Lucas?" –" I'm working on a car park design. What are you up to Hans?". "I told you, I'm working on a chair" (the same chair).

This got me thinking. What would happen if the improvement programme in Lucas' company transferred to Hans' company? Would there be an appreciation of how the

company creates value? Lucas' company is about throughput. Hans' business is about creating a fabulous design, which can take months or years.

Maybe there would be more designs emerging from the design office. There may be more products in the range. Or would the whole ethos of the company be

lost? A company that at the heart of it's being, has a long and artistic development process, which combines function and form. There may well be opportunity for improvement in Hans' development

process. But taking the wrong approach could be disastrous.

Proven frameworks can be very successful in business transformation. But there are risks in applying recipes, when ingredients differ.

As you embark on your next improvement initiative, step back and think about what's special in the organisation. Tailor your approach to the needs of the business.

www.virrata.co.uk Tailored solutions